If you have ever used condensed milk or even regular milk lactose salad (eg zero lactose) lives that a color was dark Too much, right? Don’t worry, it’s normal.

Traditional, lactose-free condensed milk

In the samples to illustrate the article, it is possible to see the difference in the color of the condensed milks. The traditional version is the least colorful of all, while the two lactose-free samples (from different brands) are colored.

- Sample 1: traditional condensed milk (8% fat)

- Sample 2: lactose-free condensed milk (8% fat)

- Sample 3: lactose-free condensed milk (8% fat)

In this case, sample 2 has color, but it is subtle. In person, it was possible to notice a greater difference when compared side by side with sample 1. And sample 3 is clearly colored.

It’s worth noting that sample 3 would expire within a week of when I took the photo, and sample 2 was still over 2 months away. Sample 2 is from a brand I’ve used before, and it’s usually very colorful too.

Can I use lactose-free condensed milk that is dark?

If you are within the validity and it was stored correctly: yes, you can use and eat it. The darker color, almost caramelized (but not caramelization) can occur due to the way lactose-free products are produced. The darker color and possible flavors are because of the Maillard reaction.

Just to remember: the Maillard reaction is a sequence of reactions that happen with some types of sugars (the famous carbohydrate, in this case, needs to be reducing sugar) and proteins (in this case, with amino acids) that in the end produce colored compounds called melanoidinas.

This change in color and other physical-chemical characteristics can occur in any brand of product, it is not specific to a particular brand. It is something that is expected to happen in the product.

Why can lactose-free products turn dark?

There are several factors that can contribute to this characteristic, what we can highlight now is the production method and time. More precisely: when the difficult lactase is added. It is worth remembering that the product will eventually become dark over time as well.

Generally speaking, there are two ways:

- The enzyme lactase is placed in milk before heat treatments to sterilize/pasteurize the product, a process called batch or batch (or batch)

- The enzyme lactase is placed in milk after heat treatments to sterilize/pasteurize the product and can be aseptic tank or during aseptic filling, a process called in-line dosing (or in-line dosing). An important detail, the enzyme used in this process must be sterile or sterilized before use.

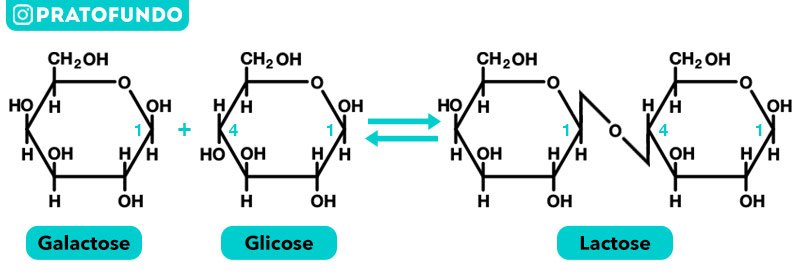

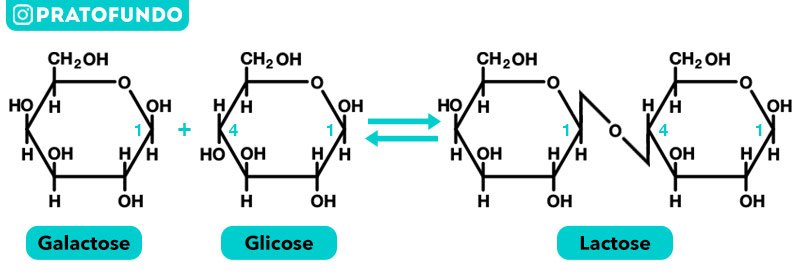

A lactose It is a reducing sugar (has free anomeric carbon) and can participate in the Maillard reaction. When the breakage of the lactose em galactose e glucosethe mixture becomes two reducing sugars. Therefore, increasing the chance of the Maillard reaction happening. Previously, with just lactose, there was only one reducing sugar.

Because of how the bond between galactose and glucose is made, the galactose molecule “loses” yours reducing capacity. The bond between galactose and glucose is beta 1-4and it is precisely the carbon 1 which needs to be free for the Maillard reaction to occur. And when lactase is added, the bond is broken and carbon 1 of galactose is free to react again. And carbon 1 of glucose was already free to react.

The method of adding the lactase enzyme and production can influence the speed at which the Maillard reaction takes place. In the process of batch/batch There may be a greater chance of the reaction happening, as it goes through heat treatment with the lactose already broken down. You combine temperature with the compounds necessary for it to happen.

The version of in-line dosing It has the advantage of separating the heat treatment and only adding the enzyme in the final stages (bottling). However, if the dosage is not done correctly and the type of enzyme is not well chosen (high purity), darkening can also occur due to the parallel activity of the enzyme (acting on proteins, increasing the amount of free amino acids). And thus favoring the reaction and production of unwanted flavors as well.

You help keep the website and videos up and running and we have really cool rewards, come find out how!

Storage and time in the Maillard reaction

However, storage and time also influence. The Maillard reaction can occur at low temperatures, The big difference is that it will take longer. The longer the product is stored, the greater the chance of reactions occurring.

It’s not a rule, but generally, lactose-free products have a “validity” smaller than their lactose equivalents. In the case of condensed milk, the traditional version lasts almost 12 months, while the lactose-free version lasts 6 months. Precisely because of these physical-chemical changes to the product.

As you can see in the examples, the darker lactose-free condensed milk would expire in less than a week. While the other lactose-free sample was still more than 2 months away.

The darkening process can also happen with the traditional version. However, generally only after a long time and the product’s expiration date has passed.

Bibliography

- DEKKER, PJT; KOENDERS, D.; BRUINS, MJ Lactose-Free Dairy Products: Market Developments, Production, Nutrition and Health Benefits. Nutrients, 2019, 11551.

- FENNEMA, OR; DAMODARAN, S.; PARKIN, KL Fennema Food Chemistry. Ed. Artmed.

- LUND, MARIANNE N.; RAY, COLIN A. Control of Maillard Reactions in Foods: Strategies and Chemical Mechanisms. ACS Publications. J. Agric. Food Chem. 2017, 65, 23, 4537–4552.

- NELSON, David L.; COX, Michael M. Lehninger’s principles of biochemistry. Ed. Artmed.

- SUNDS, AV et al. Maillard reaction progress in UHT milk during storage at different temperature levels and cycles. International Dairy Journal77, 56–64, 2018.

- TROISE, AD et al. The quality of low lactose milk is affected by the side proteolytic activity of the lactase used in the production process. Food Research Internationalv. 89, p. 514–525, 2016

- Tetra Pak. Aseptic dosing of heat-sensitive ingredients: Tetra Pak® Aseptic Dosing unit E.

Sign up for our newsletter and stay up to date with exclusive news

that can transform your routine!

Warning: Undefined array key "title" in /home/storelat/public_html/wp-content/plugins/link-whisper-premium/templates/frontend/related-posts.php on line 12

Warning: Undefined array key "title_tag" in /home/storelat/public_html/wp-content/plugins/link-whisper-premium/templates/frontend/related-posts.php on line 13