Wheat flour, a super common ingredient and day to day. It seems simple, right? To make that delicious cake or a super cute bread.

But there is so much, but so much behind it: it’s fascinating! (And confused).

It’s simple, but as they say: you can complicate.

The detail is that each country classifies wheat flour in a different way and they do not always beat each other. Some countries use the ash content, others refining (mowing) and some of the mixture of various factors.

Not to mention the types of wheat that directly influence the characteristics that the flour will have, so how will it be its use as well.

And this mixture of classifications can generate some doubts and confusion when we look at recipes coming outside or we hear about such protein content.

The purpose of the article is not to say which flour brand you should use, whether or not you should eat it and the like… But provide information for you to make your choice, come on!

What is wheat flour?

It is the product obtained by milling the wheat grain (Triticum sp.). Let’s elaborate a little more:

Wheat Flour: product made with wheat grains (Triticum aestivum L.) or other species of wheat of the genus Triticum, or combinations by means of crushing or milling and other technologies or processes.

Normative Instruction 8/2005

The species Triticum aestivum is also called common wheat and there are more than 10 species within the genus Triticum. Not to mention the thousands of varieties (cultivars) of T. aestivum each with its characteristics.

Another species used is Triticum, but its main use is in the manufacture of semolina (or semolina). And most laws make a separation between the use of T. aestivum and durum.

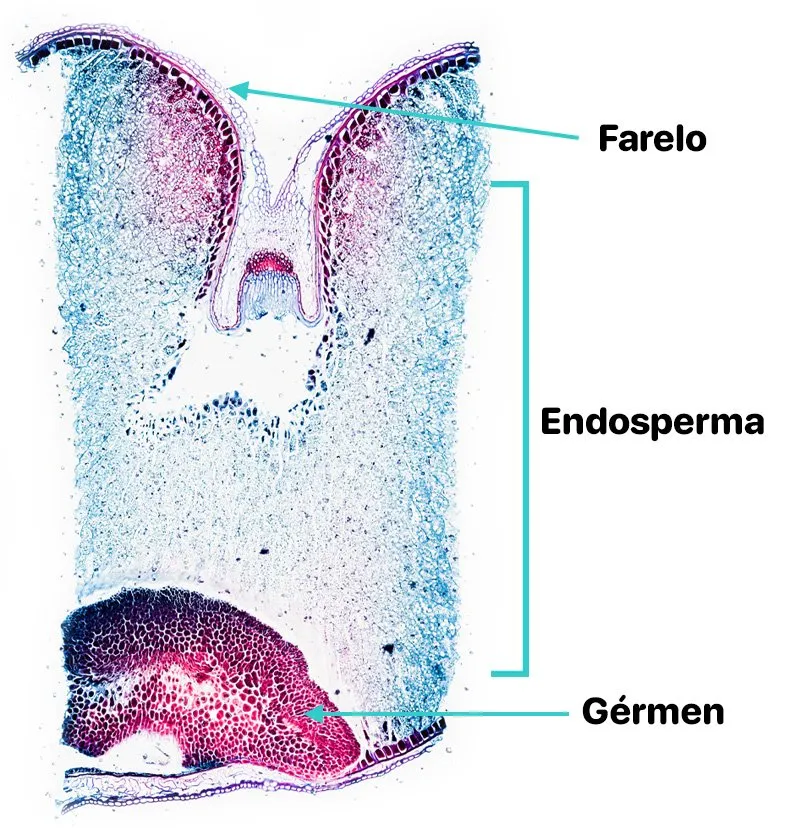

Wheat grains can be classified in a variety of ways either by color, planting season and hardness. Hardness refers to the texture of the wheat endosperm (wheat grain region that presents starch and gluten-forming proteins) that depends on the interaction of starch and proteins and their types. Within the types of wheat, the T. durum is the hardest.

- Hard wheat: requires more strength during grinding, starch granules break down during the process which results in a greater amount of damaged starch. During grinding, the first fracture points are in the structure of the cell wall, indicating that the binding of the internal content (amedium and proteins) is strong. It has higher protein content and indicated for breads.

- Soft wheat: requires less strength during grinding, starch granules break down in less quantity. The fracture point is due to the internal contents of the cells, indicating that the internal interaction is weak. Compared with the hard, the protein content is lower and indicated for cakes and cookies.

- Durum wheat: the hardest variety that requires the most strength, despite having a high content of proteins that make up gluten, is not used for breads in general because of the strong interaction and not being quickly available. Therefore, it is not so common to have flour (even flour) of durum wheat. Although it is possible, the process would result in a high amount of damaged starch. Grinding can break the starch bean, but not the strong interaction of starch with proteins.

It is important to note that depending on the reference there may be confusion regarding the hard name and durum. Both durum and soft wheat are varieties and cultivars of the species T. aestivum (and/or other authorized species), while durum is only for T. durum (and varieties within the species).

Whole wheat flour indicates the complete use of clean wheat (having the endosperm and bran) and may or may not have the germ. Because it contains practically the whole grain, so more fats can also: it can become rancid faster. Therefore it can cost more, the potential loss along with the law of supply-search costs the product.

The basic composition of wheat flour is 65% starch, 12% protein, 14% moisture (water), 2% fats and the rest consists of non-amid-rid polysaccharides and inorganic components (mineral salts), can vary if it is whole. The amount of calories are around 350kcal (for white wheat flour) and 330kcal for the whole grain (every 100g).

Within the proteins we have the famous gluten: which is formed by the groups of gliadin proteins and glutenins in the presence of water and agitation (the beating and beating). Despite being a small fraction of what forms flour, the paper in texture, structure and moisture are huge. I’ve talked about, read more: What is gluten?

Support the PlateFund

You help keep the site and videos on the air and we have very cool rewards, come to know how!

Such quality of flour depends on several factors from the type of wheat used to how the grinding was mademoagem. This reflects in the water absorption capacity, flour strength and what is the best use for each type of preparation.

There are several tests to make this determination within the wheat flour industry. Below we will comment on some of them, it is a bit technical. I tried to make it simpler, but it is data that has little relation to the day to day of the consumer.

Alveographer (Force)

An analysis using equipment called Chopin Alveograph that determines the strength of flour and simulates the fermentation process. For those who have seen something about flour, it calculates the famous W index (W index) that is usually linked to gluten.

The measured parameters are:

- P (tenacity): is the maximum pressure required to expand the mass. On the graph is indicated by the maximum height of the curve.

- L (extensibility): shows the ability of the dough to stretch until it bursts, being indicative of the volume of bread.

- P/L (curve balance): is the balance between P/E. A generic guide, for breads (balanced tedries 0.50-1.20), cakes and biscuits (an extensible blands ?0.49).

- Index of elasticity (Ie): compares the pressure after 200mL of air was injected into the mass with the maximum pressure (P).

- W (forming energy): indicates the power or work of deformation of the flour. It is the area formed by the curve within the graph.

The value of W alone does not indicate much, as it depends on the other factors P and L. You can have two flours and both have a W of 300. But one has a higher P and the other a smaller P, for example.

So, to know the strength of the flour in a technical and punctual way: you need an alveographer. Not to mention that each company will have parameters for its formulation, that is, what may be good for one does not mean that it will be good for another.

The analysis helps to determine:

- Classify wheat according to its strength and determine which applications are the most ideas.

- Improve the mixtures (blends) of flour in the mill to arrive at the desired characteristics.

- Evaluate the conformity of flour.

- Adjust mixing time de misturaand hydration.

- Decide if you need to use improvers.

Theor of ashes

One data you will see throughout the text is this gray content that is:

- The mineral residue that remains after the flour is incinerated (burned) in a muffle (it is an oven that reaches high temperatures).

- And in the case of wheat, the ash content varies according to the amount of bran and germ of the wheat grain remains in the flour. The more gray, the more bran and germ.

It is an important analysis more from an industrial and/or mill point of view to help determine whether the refining/mowing process is being efficient or not. The higher the ash content indicates that the more parts of the bran and germ are being processed together from the flour.

The values may vary depending on how the analysis (mot base or dry base) was performed, in addition to the variety of wheat and planting conditions.

In short:

- More ash: more whole grains, higher number, darker flour.

- Less ash: fewer whole grains, lower number, whiter flour.

Farinógrafo (Hidration)

The ability to hydrate, or rather, water absorption of flour is a given data obtained by another analysis made with the Farinography. This helps to determine the quality of flour.

Measures the deformation resistance of a flour/water mixture against blades that beat the dough with specific speed and temperature, torque.

The data obtained are:

- Water absorption (%): the amount of water added so that the farinograph curve acquires the standard consistency in the line of 500 farinographic units. Useful parameter for adjusting the amount of water when there is change of flour.

- Mass development time (TDM): interval between the addition of water to the maximum consistency point immediately before the first indication of weakening. In practice, it is used for adjustments in mixing time. Stronger flours with more protein have a longer development time than weak flours with the same particle size and distribution.

- EstabilidadeStability: the time difference between the time of arrival time of the curve at the 500 UF line and the starting time when the curve is below. It is indicative of the resistance of flour regarding mechanical treatment (sova, mix), mixes too much. Stronger flours are usually more stable than weak ones within the same type of wheat.

- Mix tolerance index (ITM): difference between the top of the curve at its optimum point and five minutes after it was hit. Indicates the speed at which the structure of gluten breaks down after reaching its maximum potential.

The parameters of the analysis may vary according to:

- Water absorption: damaged starch content, gluten-forming proteins, hemicellulose, cellulose fiber from bran, granulometric distribution of flour.

- Mass development time: chemical conformation of glutenins, granulometric distribution of flour, amount of hemicellulose.

- Stability: chemical conformation of glutenins, cellulosic fiber from the bran

- Mixed Tolerance Index: Chemical Conformation of Gluten.

– Is it healthy?

I will not go into the question if it is bad, but I will limit myself in saying that there are two very specific cases that it is not recommended to eat wheat and/or flour wheat: if the person is celiac (actually) and/or allergic to some component present in the wheat. lembrandoCeliac disease is an autoimmune disease and not allergy.

Want to know more about Glútengluten? Read more: What is gluten?

How to Calculate Protein Containing

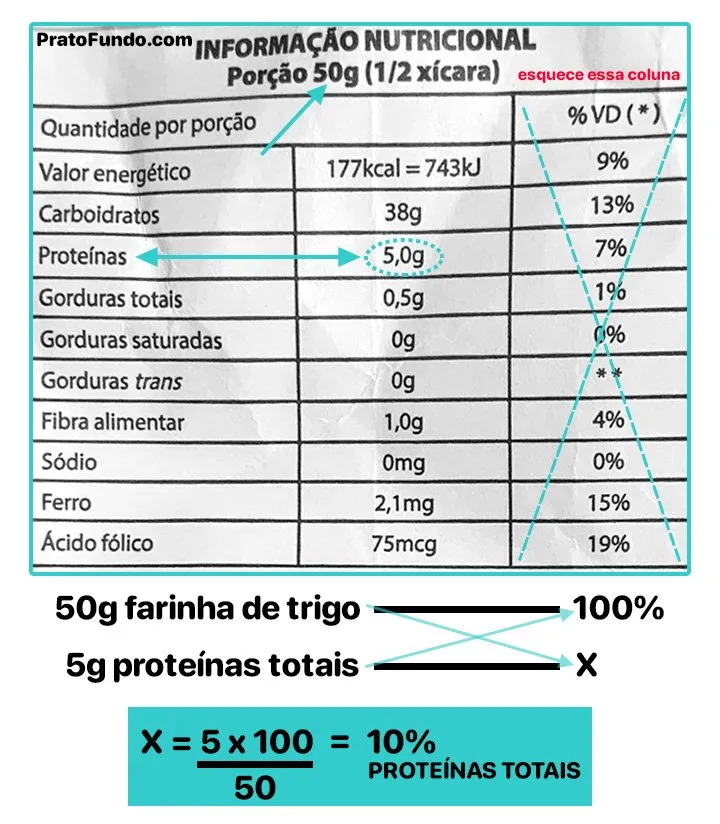

First of all: it is just a generic information. What do you mean?

We will calculate indirectly indiretausing the nutritional table that comes on the packaging. And we need to remember: the values in the table are an average of values and made by sampling. Therefore, variations occur, after all, the manufacturer will not exchange the packaging all the time.

So don’t get too attached to that value. Does it help to have an idea? Yeah. Yes. But alone means nothing. And another important detail: it is the total protein content and not just gluten only.

Forget the %VD column (daily values), it will not be used in this calculation.

See that the portion is 50g of wheat flour and in this amount the flour has 5g of total proteins, right?

So 50g of flour is our 100% and we want to know how much these 5g of protein represent in percentage.

The account is a rule of 3, so it multiplies cross and then isolate the X. And solving the mathematical operations we get to the value of 10% of total proteins. Read: every 100g of wheat flour, 10g are of total proteins.

That is, all the proteins present in wheat flour: the gluten-forming and the gluten non-forming.

There is the analysis of wet and dry gluten content that consists of forming gluten in the flour and washing the mass formed to remove the soluble solids in water and what is left is gluten. If you want to know how you do, I recommend reading Gluten Washing Tests.

Wheat flour in Brazil

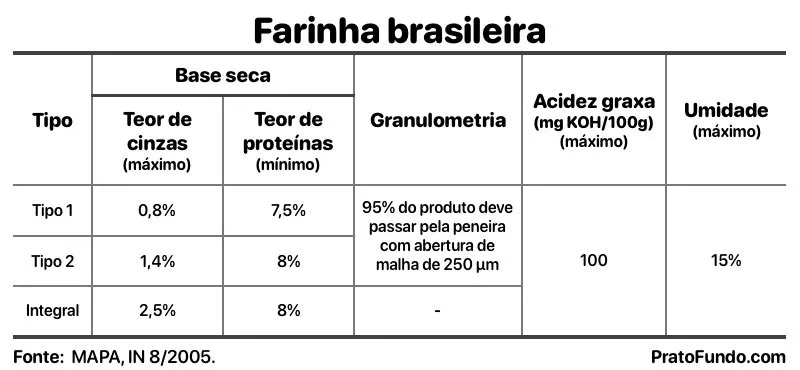

In Brazil the classification of wheat flour follows Normative Instruction 8/2005 of the Ministry of Agriculture (MAPA), being: Type 1, Type 2 and Integral.

The definition of Normative Instruction for wheat flour is specific to the species Triticum aestivum L.) or other wheat species of the genus Triticum, except for wheat-made flours of the species Triticum durum Desf..

In the case of Semolina the definition is given by the CRC 14/2000:

- Semola or semolina of wheat: is the product obtained from the species Triticum aestivum or other species of the recognized genus Triticum (except Triticum), through the grinding process of the wheat grain benefited, with an ash content of 0.65% on the dry (maximum) dry base.

- Semola or semolina of wheat last: it is the product obtained from Triticum durum Desf., through the grinding process of the benefited grain, with an ash content of 0.92% on the dry (maximum) base.

An important detail: the amount of protein in the table should be seen with a certain lightness. The content of this classification is made on a dry basis, that is, to reach this value the humidity is disregarded in the amount analyzed.

As you can see, they take into account data that say little to us – end consumers. But these are the parameters from a technical point of view and legislation for domestic use. It also exists for IndustrialIndustrial, but here it is not so important for us.

Our flour and wheat are imported! The national production of wheat is not enough to serve the country, so it is necessary to come from outside. According to data from the Brazilian Wheat Industries Association (Abitrigo) we import wheat from Argentina, the United States, Paraguay and Uruguay

Is it bad?

There is a debate that national wheat (and flour) is bad that ends up splashing on the average consumer (and changing the meaning a little). It involves market lobbying, unstandardized management, market uncertainty and lack of incentive.

For the consumer this idea of being bad is in the sense of using wheat flour to make bread. It would be bad because it didn’t have enough protein content. So bad for you isn’t. For example, you’ve made cake and pie and everything is fine, right? But that perhaps it is not ideal for bread, it is another concept.

Translated: use the flour and see the result. Did the recipe get good? Did you achieve the expected result? So she is good for you and your process. The result didn’t look like you wanted? It may be that the flour is not ideal for the recipe and / or the process had flaws.

Additives and improvers

Yes, they can be added and follow Resolution No. 383, of 5 August 1999 of which substances can be used. Not all flours put on and when they do this should be described in the ingredient listing.

- Benzoyl peroxide: is the only whitening agent authorized in Brazil by RDC 383/99. Sometimes we see sensational calls sensational fans have bleach that plays with the semantics of the word. Wheat flour may have a yellowish tint due to Xanthophyll (pigments within the carotenoids). It is possible to whiten the flour naturally with time and temperature (maturation and aging) due to the action of oxygen.

- Oxidizing agents: such as ascorbic acid and azodicarbonamide aid in the formation of disulfide bonds (bonding between sulfurs) between gluten-forming proteins, gas retention, changing consistency.

- EnzimasEnzymes: Flour naturally has enzymes such as amylases (dying out) and proteases (break protein), but they may not be in sufficient quantity or did not present the activity that the manufacturer wants. Then, the addition of amylases, proteases and lipoxygenase is allowed.

Regarding the additives/improvers above, I have already read listed in products focused on trade as premixtures for the production of breads and cakes, and specific flours. For the flour for the final consumer, I know it exists, but I have never seen to buy. I’m not going to get into the credit if it hurts or not, will I stop using flour? No, right, right, right.

It is prohibited since 2001 to use potassium bromate and sodium in wheat flour by Law No.10.273 of 5 September 2001. And sodium de sódiois not listed in RDC 383/1999, so it cannot. If you know someone who uses it, it does not undo the prohibition and the person is going against the law, not to mention the huge deviation of character, right?

Brazilian flour is obligatory enriched with iron and folic acid (vitamin B9) since 2002 by RDC 344/2002 and since 2017 the requirement has been expanded to corn flour also by RDC 150/2017.

The addition of iron is a way to combat iron deficiency anemia (anemia caused by lack of iron) and folic acid to prevent neural malformation of the fetus during pregnancy as myelomeningocele.

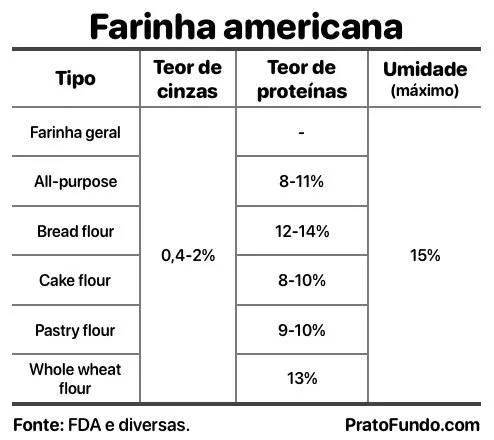

Wheat flour in the United States

For those who have the habit of looking at American recipes have already had seen some of these names: All-purpose, Bread flour and so on.

I believed these classifications were official of the FDA (Food and Drug Administration, Anvisa). But they are not. They are more commercial and according to what the industry offers. Cake flour was invented in 1894 by the Swans Down company.

The FDA (21CFR137.105) has a general definition for wheat flour, as well as the MAPA:

is the food prepared by crushing and sieved of clean wheat, except for durum wheat and red wheat durum.

- It can be added: to compensate for any natural deficiency of enzymes, malty wheat, malted wheat flour, malted barley flour or any combination of two or more. But the amount of malted barley flour used is not more than 0.75%.

- Harmless preparations of alpha-amylase obtained from Aspergillus oryzae, alone or in a safe and suitable vehicle, may be used.

- When tested for granulation: at least 98% of the flour passes through a sieve with weft with openings not larger than those of the wire weft designated 212 (micro) m (No. 70).

- The percentage of ash contained in it, calculated on a dry basis, does not exceed the sum of 1/20 of the percentage of protein contained in it, calculated on a dry basis, plus 0.35. (slaughter around 0.4-2%)

- Its moisture content is not more than 15%.

- It may contain ascorbic acid in an amount that does not exceed 200 parts per million as a mass conditioner. It cannot be used for tampering to hide low quality or defect.

In summary: flour can have mixture of other flours for adjustments, can be enriched, has a particle size, ash between 0.4-2%, humidity less than 15%, and can add ascorbic acid as conditioner.

The types of wheat flour that exists on the American market:

- All-Purpose Flour (flaur for all uses): it is a mixture of durum and soft wheat, can also be called plain flour (simple flour). Protein content is around 8-11% and is the most common. It can be bleached or not bleachedunbleached, and enriched. As the name says, it is for general use from cake to bread.

- Bread Flour (bread flour): made with durum wheat with high protein content and has more protein than All-purpose that is around 12-14%. Generally, not bleached and may contain ascorbic acid (vitamin C) as a enhancer that acts on volume and texture. As the name suggests, ideal for breads and fermented recipes.

- Cake Flour (cake flour): super fine texture and made with common wheat with a high starch content. Protein content around 8-10% is usually bleached (with chlorine gas) that leaves flour slightly acidic, cake pastas are ready faster and the fat distribution is more balanced influencing the texture. As the name implies: ideal for cakes and recipes in which the texture should be soft and brittle.

- Pastry Flour (co-making flour): made with common wheat and would be between All-purpose and Cake flour in its use and protein content 9-10%. It has less starch than the Cake, leaves the texture soft and brittle.

- Self-Rising flour (flour with yeast): low-protein flour with salt, growth agents (leaven or baking soda) with acidic substances to react and produce carbon dioxide. In general, it would be an All-purpose with yeast.

- Whole wheat flour: the granulometry should follow the definition “no less than 90% passes through a sieve of 2.36 mm (no 8) and not less than 50% passes through a sieve of 850 ?m (no 20)”, maximum humidity of 15%, can be added of ascorbic acid and enzymes, have bleached presentation and not bleached. Protein content is around 13% and usually made with durum white wheat in spring.

The American options are clearer for which each type of flour serves, it is easier to choose which one to use. And some brands report the content of proteins on the package without the need to analyze the nutritional table.

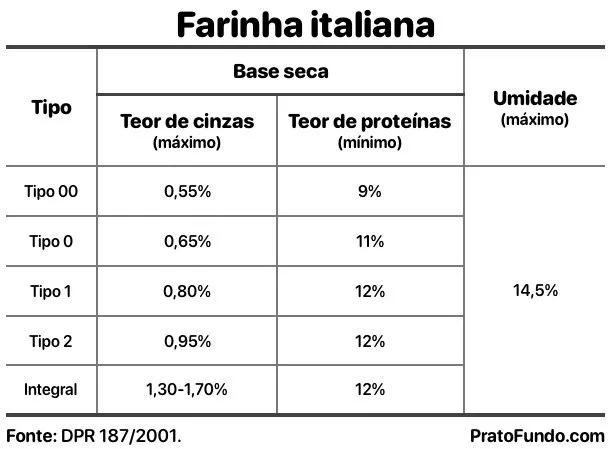

Wheat flour in Italy

The Italian classification is complicated and simple at the same time. The law also uses several factors, one of them being the content of ash and proteins.

However, many sources also indicate the type of refinement (moying and sieving for removal of parts of the grain) from the wheat to have the five levels: 00, 0, 1, 2 and whole. They say they are part of Italian law. But Law 580/1967 and the most recent decree DPR 187/2001 of the MIPAAF (Ministero delle politiche agricole alimentari e forestali) make no mention of this that in Italian is well-known.

The Italian law defines wheat flour as:

Flour of common wheat (farina di grano tenero) is the name to be used for the product obtained by crushing/mowing and then sifted from the common wheat and that had the impurities and foreign bodies removed.

Whole flour flour flour (farina integrale and di grano tenero) is the name to be used in the product obtained by direct milling of common wheat and had the impurities and foreign bodies removed.

DPR 187/2001

There is also the definition of flour made with durum wheat (hard linum, Triticum durum) which is used to produce grano durum semolina (semola di grano hard), grano durum semolato (hard grano dimolate), whole grano durum semolina (semola integrale di grano hard).

The law does not talk about the flour of Manitoba (farina di Manitoba) which is another trade name for designating flour made with wheat from the province of Manitoba in Canada. It is found in all classifications of the Italian law list for common wheat.

The deauthic di abburattamento is related to the reduction of the wheat grain after the process and which makes up the flour. 00 being 00the thinnest and the integralintegral the thickest, in general lines. To make it a little more confused, some producers don’t see abburattamento as a refinement and that would be different things.

I reviewed the Italian ministry website, but found nothing about the abburattamento. I may have let some go by not knowing Italian per se, anyway, I will leave here the classification I have read several times about this:

- Type 00: has suffered a 50% reduction, is the most refined and comes from the endosperm;

- Type 0 : suffered a reduction of 72%;

- Type 1 : suffered a reduction of 80%;

- Type 2 : suffered an 85% reduction;

- Integral: contains all the internal and external parts of the ground grain.

Ultimately, the detail is: everything ends up in the matter. Because of the nomenclature, many people find that 00 flour is weak relative to protein content. This is not necessarily true, it is possible to find 00 Italian flours with 12% protein content, for example. (See: The Pizza Lab: On Flour Types, Foams, and Dough)

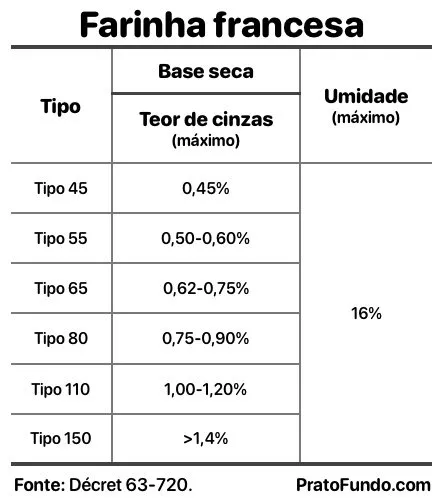

Wheat flour in France

French flour uses the ash content to make the classification and Germany follows a very similar system.

The parameters for the types of flour (45, 55, 65, 80, 110, 150) were defined by Decree No. 63-720 of 1963. And the values refer to the amount of ashes in 100g of flour.

And by mid-2016, the type 45 and 55 flours need to follow the standards below. But it was repealed by Decree 2016-884.

- Type 45: W/Chopin above 220; G/Chopin above 19; Protein above 11%.

- Type 55: W/Chopin above 220; G/Chopin above 19; Protein above 11.5%.

- W and G of Chopin are quality parameters used in the industry to test flours, and are linked to the gluten content. A high W indicates that flour is strong.

Some texts cite Decree No. 93-1074 as having requirements for the French bagwpole. Not necessarily, but defines the criteria so that breads can use specific names:

- Pain maison (housebread): or equivalent can only be used if the bread has been fully crumpled, worked and cooked at the place of sale to the final consumer. However, this denomination can also be used when bread is sold out of place to the final consumer by the professional who ensures that the operations of kneading, modeling and cooking occur in the same place.

- Pain of tradition française(French tradition)Pain traditionnel français(French traditional)Pain traditionnel of France(traditional French do’tread): or a combination of these terms may only be sold ifhave not been frozenat no time during its manufacture,without additivesand are produced from a mass having the following characteristics:

- consist exclusively of a mixture of baked wheat flour, drinking water and table salt;

- To ferment with bread leaven (Saccharomyces cerevisiae) and levain, …, or only one of these agents for the alcoholic fermentation of bread;

- Optionally, contain in relation to the total weight of the flour used, a maximum proportion of: 2% of f-ves flour, 0.5% of soybean flour and/or 0.3% of wheat malt flour.

And reading French blogs it was possible to notice the same thing that happens with Italian flour. The names type 00 and type 45, for example, are a category of flours. There may be several types of flour 00 and 45 that vary the protein content.

Very Long; Not Li

I got you jumped, right? I recommend you read! But let’s go!

The table below is an attempt to fit the various types of flour according to the laws of each country. But as you can read in the text, it is always possible. Then, look at the picture with a certain lightness and not as a definitive thing.

- Flours are different because of the legislation and use of consumers in each country. So flour type 00 only imported and usually Italian. And so on.

- The characteristics of each flour depend on the wheat used, such as planting conditions and the milling process (and refining).

- For the most common recipes of Brazil of cakes, pies and cookies (ours or Americans) any national flour will give you a good result. He did, ate and found it tasty? That’s great. They are recipes that do not require a strong gluten structure, but rather delicate, which much of the national flours deliver.

- For breads with American and European style, really, will look a little different even because of differences in the characteristics of flour. But it does not mean that flour is bad. Not to mention that the correct technique counts a lot. Try to find flour with a higher protein content.

- Know more about fermentation and technique with bread without besme.

- What is the best flour? Test in your recipe, see how the result was. Did it look like you wanted? It’s hot?

- All flour has ashes. But not what you think! From a technical point of view, ash content refers to the inorganic and mineral content of flour that comes from wheat. It is possible to relate to the level of refining/mowing: when more bran and germ, the higher the ash content.

- Flour may present additives and enhancers, but when they are added should be listed in the ingredients.

- Both wheat and corn flour are enriched with iron and folic acid (vitamin B9) for the prevention of iron-deficial anemia and fetal neural malformation during pregnancy, respectively.

- Want to use whole meal? There is no magic formula ready, after all, they are flours with different properties. Make the recipe as indicated a few times to know how you should look and then go test the exchange. Food52 has a very cool post about: Whole-Wheat vs. White Flour: What’s the Difference?

- Changing flour does not always be the same, but there are cases that adaptations are necessary. Tessa from Handle The Heat made a comparison between Cake flour, All-purpose and Cake flour in the trick.

- You can add more gluten in flour with the use of vital gluten or gluten flour that are sold in the home of natural products. To know the amount you need to use Gauss Elimination to be sure or use the Flour Math calculator.

- The famous W index is a quantity calculated by Alveograph equipment and is usually associated with the strength (and gluten) of flour. But alone does not say much, it needs the P (thenity) and L (extensibility). And this analysis is in the industry, in the packaging does not come.

- It has how to calculate the total protein content of flour, I showed in the body of the text read there. And it is also possible to know the gluten content has by the method of washing gluten, but sincerely, for home use has little meaning.

- If you don’t have any health conditions like allergy and celiac disease: Gluten is not the villain as they like to paint.

References

- ABIP. Brazilian Association of the bakery and confectionery industry. Technology of baking and confectionery, 2011.

- ABITRIG. Brazilian Association of Wheat Industries. Import of wheat 2020.

- ABITRIG. Brazilian Association of Wheat Industries. Imports of wheat flour 2020.

- ATWELL, W.A.; FINNIE, S. Wheat flour: american association of cereal chemists international. Elsevier, 2016

- BAKERPEDIA, 2020.

- BERTON, Benjamin et al. Measurement of hydration capacity of wheat flour: influence of composition and physical characteristics, Powder Technology, v.128, issues 2–3, 2002, p.326-331.

- Brazil. Law n. 10,273 of September 5, 2001. Official Journal of the Federative Republic of Brazil, Section 1, Electronic, 6 Sep. 2001, p. 15.

- BRAZIL, ANVISA. National Health Surveillance Agency. RDC n. 383 of 5 August 1999.

- BRAZIL, ANVISA. National Health Surveillance Agency. RDC No. 14 of 21 February 2000.

- BRAZIL, ANVISA. National Health Surveillance Agency. CRC n.344 of 13 December 2002.

- BRAZIL, ANVISA. National health surveillance agency. Guide to good nutritional practice: French bread, 2002.

- BRAZIL, ANVISA. National Health Surveillance Agency. RDC No. 60 of 5 September 2007.

- BRAZIL, ANVISA. National Health Surveillance Agency. Technical report no. 39, of 7 January 2009.

- BRAZIL, ANVISA. National Health Surveillance Agency. RDC n.53 of 7 October 2014.

- BRAZIL, ANVISA. National Health Surveillance Agency. RDC n.54 of 7 October 2014.

- BRAZIL, ANVISA. National Health Surveillance Agency. RDC No. 150 of 13 April 2017.

- BRAZIL, MAP. Ministry of Agriculture and Supply. Normative Instruction No. 1 27 Jan. 1999. Wheat Identity and Quality Standard. Official Gazette of the Federative Republic of Brazil, Brasília, DF, 27 Jan. 1999, Section 1, n. 20, p. 3.

- BRAZIL, MAP. Ministry of Agriculture, Livestock and Supply. Normative instruction n. 8 of 3 Jun. 2005. Technical Regulation of Identity and Quality of Wheat Flour. Official Gazette of the Federative Republic of Brazil, Brasília, DF, Jun 3. 2005, Section 1, n. 105, p. 91.

- Centro Informazione Farine. The Italian munis.

- COSTA, M.D.G.D. et al. Technological quality of grains and flours of national and imported wheat. Ciênc Tecnol Aliment 2008;28:220-5.

- CUNHA, G. A. da. Wheat in Brazil: history and production technology. Step Background: Embrapa Trigo, 2001.

- Embrapa. Brazilian Agricultural Research Company. Wheat.

- the United States. U.S. The department of agriculture. Wheat Sector at a Glance.

- the United States. FDA, Food and Drug Administration. Code of Federal Regulations Title 2: 137 Cereal Flours And Related Products.

- FIGONI, P.I. How baking works: exploring the fundamentals of baking science. John Wiley and Sons, 2010.

- FRANCE. Légi France. Décret no 63-720 du 13 juillet 1963 relatif à la composition des farines de blé, de seigle et de méteil.

- FRANCE. Légi France. Décret no. 93-1074 du 13 septembre 1993 pris pour l’application de la loi du du 1er à?t 1905 en ce qui relatee certain catégories de pains.

- FRANCE. Légi France. Décret n 2016-884 du 29 juin 2016 relatif à la partie réglementaire du code de la consommation.

- GUTKOSKI, Luiz Carlos et al. Effect of grain maturation period on the physical and rheological properties of wheat. – Ciênc. Tecnol. Aliment. (online). 2008, vol.28, n.4 (cited 2020-07-02), pp.888-894.

- ITALY. Legge 4 luglio 1967, n. 580. Discipline per lavorazione and commercio dei cereali, degli sfarinati, del pane e delle paste alimentari.

- ITALY. MIPAAF, Ministerolle agricole agricole alimentari and forestali. Regolamento per la revisione della normativa sulla producedione e commercializzazione di sfarinati and paste alimentari, the standard dell’articolo 50 della legge 22 febbraio 1994, n. 146.

- Paul, A. et al. Wheat (Triticum aestivum L. and T. turgidum L. ssp. durum) Kernel Hardness: II. Implications for End-Product Quality and Role of Puroindolines Therein. Reviews in Food Science and Food Safety, 12: 427-438.

- RAM, S. Cereals: processing and nutritional quality. New India Publishing Agency, 2009.

- SKYLAR, B. T echnology of cereals, pulses and oilseeds. Scientific e-Resources, 2019.

- SNA. National Society of Agriculture. Brazil already produces the best wheat in the world, but needs to expand its production, 2017.

- The European flour millers. Wheat Flour standards in European Union, Wheat, Flour, Climatic Changes and New Trend, 2013.

- VACLAVIK, Vickie A.; CHRISTIAN, Elizabeth W. Essentials of Food Science. Springer Science & Business Media, 2007.

- ZILI, Slaana et al. Characterization of proteins from grain of different bread and durum wheat genotypes. International journal of molecular sciences vol. 12,9 (2011): 5878-94.

Thanks

I would like to thank the supporters PratoFunders: with this support I can dedicate myself to writing more complete and detailed texts like this. Learn how you can be a part of: Support the Fucking Plate!

Sign up for our newsletter and stay up to date with exclusive news

that can transform your routine!

Warning: Undefined array key "title" in /home/storelat/public_html/wp-content/plugins/link-whisper-premium/templates/frontend/related-posts.php on line 12

Warning: Undefined array key "title_tag" in /home/storelat/public_html/wp-content/plugins/link-whisper-premium/templates/frontend/related-posts.php on line 13